|

Xiamen XDE M&E Industry Co., Ltd

|

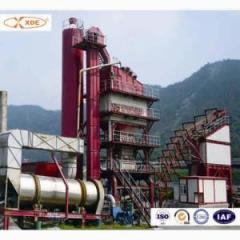

Double Drum Asphalt Mixing Plant

| Payment Terms: | T/T,L/C |

| Place of Origin: | Fujian, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Double Drum Asphalt Mixing Plant

Features:

SLHB-8, SLHB-10, SLHB-15, SLHB-20, SLHB-30 Double Drum Asphalt Mixing Plant SLHB-8 is the asphalt mixing plant with smallest capacity, which mobile double drums asphalt mixing plant, consists of aggregate elevator, burner, dryer, asphalt weighing conveyor, filler weighing conveyor. finished-product hopper(optional).cyclone dust collecting system, trailing chassis, PLC programmable electrical control cabinet, automatic weighing hopper(optional),coal grinding and powder feeding device etc. small area ,can be dragged and short installation period, wide scope of fuel. Easy operation; easy maintenance, reliable and compactable good quality of finished product high technology, automatic. high degree of standardization, apply to the asphalt road's construction and maintenance.

The plant combines the intermittent dryer and drum mixer as the whole structure, and the mixer can be dragged, and it occupies small area and is easy to transfer from site to site and install. The mixer is reliable, compactable and automatic with wide scope for fuel application, easy operation, convenient maintenance, good quality of finished products, high technology and high degree of standardization, applying to the high graded asphalt road's construction and maintenance.

Parameters:

1.Cold Aggregate Supplying System

Cold aggregate is weighed and elevated into the drying drum. We have Three-bins and five-bins aggregate batcher.

2.The Burning System.

Burner is available for both coal and oil. Customers can choose either freely. (If you choose the coal burner, a coal breaker is needed)

3.The Drying Drum And Mixing Drum

The drying drum and the mixing drum are integrated design which reduces customers' cost.

4. Dust Collecting System

The Cyclone dust filter is the basic configuration, and the bag filter and water filter is for optional. The dust collecting system can help you to reduce the pollution.

5. Finished storage bin

Convenient for finished product transferring.

6. Control system

PLC control and touch screen make the switch between auto operation and manual operation freely.

SLHB-8 | SLHB-10 | SLHB-15 | SLHB-20 | SLHB-30 | ||

Capacity | 8tph | 10tph | 15tph | 20tph | 30tph | |

Power | Diesel | 23kw | 27kw | 32kw | 45kw | 63kw |

Coal | 39kw | 43kw | 51kw | 70kw | 84kw | |

AG Batcher | 3*3m3 | 3*3m3 | 3*3m3 | 3*3m3 | 3*5m3 | |

Storage Bin | 5t | 5t | 5t | 5t | 9t | |

Product Temp. | 120-180 Celsius | |||||

Fuel Consumption | Diesel: 5-8kg/t, Coal: 13-15kg/t | |||||

Materials Scope | Bitumen sand; Bitumen broken stone, Asphalt concrete | |||||

Control Type | PLC programmable electrical control cabinet | |||||

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35